Reducing Costs for Offshore Wind Farm Maintenance and Operations

Since the early 2000s there has been a primary focus on the development and construction phases within the offshore wind industry. Now, with increasing numbers of wind turbines being commissioned, there has been a shift towards an almost independent Operations and Maintenance (O&M) process due to the logistical challenges and costs associated with not only building, but maintaining offshore wind farms.

What are the Financial Risks Associated with O&M?

Turbine Downtime

Once a wind turbine is operational there are a number of challenges that can affect the financial performance of the project. If you do not get on top of operations and maintenance there can be a significant reduction in revenue due to downtime. The obvious problem relates to the reduction in electricity production, but you also have to add the cost of carrying out any required repairs. If conditions are too unsafe to carry out repairs it can cause downtime of hours, or even days.

Unpredictable Costs

With each offshore wind farm there are different factors that make it difficult to accurately predict costs. This can be down to the number and the size of the wind turbines in place, the exact location in terms of distance from the shore and the specific environment, as well as water depth and sea conditions.

Managing Vessels and Personnel

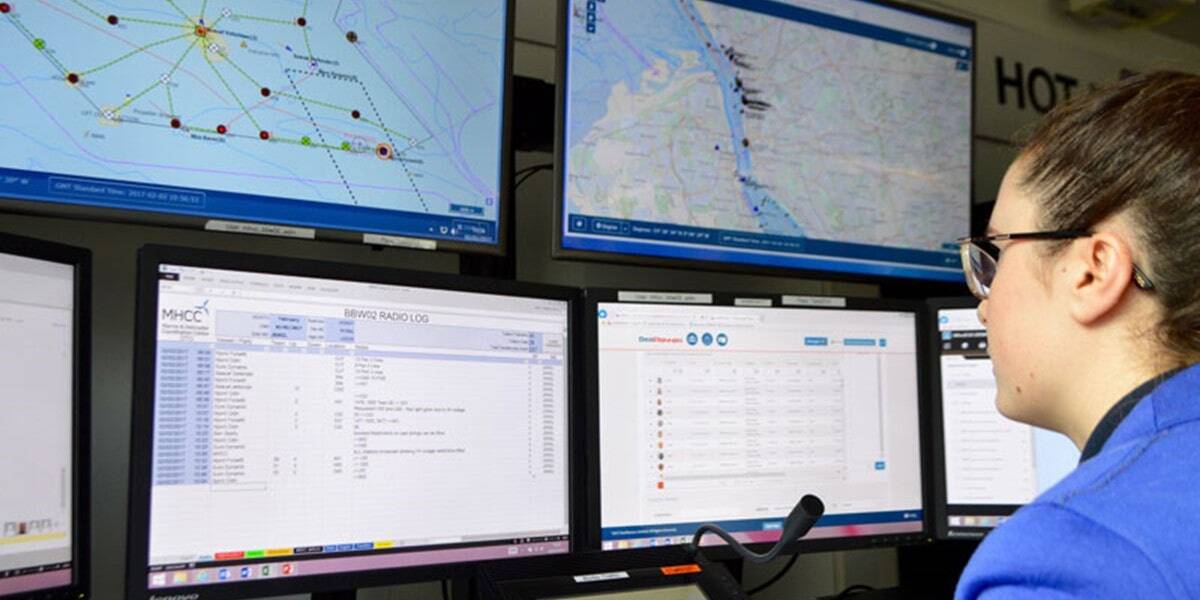

On any given day there are countless vessels and personnel traveling to and from an offshore wind farm. The management of this transport is crucial to the effectiveness and smooth running of operations and maintenance. Monitoring the location of personnel and vessels will not only save time in an emergency but will also provide crucial data in the case of any legal claims regarding an incident.

Changeable Weather and Sea Conditions

With any maintenance issues for an offshore wind farm the weather and sea conditions will always have an impact on the ability to fix a problem. Gaining access for both scheduled and unscheduled maintenance and repair works is a problematic undertaking that requires close monitoring.

Legality of Lack of Training

If personnel are involved in an incident that they have not been fully trained in there can be legal implications and the high costs associated with that. Installing a framework of in-depth training and a management of all personnel and relevant certification is a necessity.

Increasing Distance to Shore

As more wind turbines are being constructed, further from the shore, maintenance becomes a bigger issue. Not only is the risk of equipment failure greater due to the harsh conditions, but in the case of needing repair, transit time for technicians and equipment naturally increases.

Cost savings are achievable if you have the right system in place to help you effectively manage Operations and Maintenance for an offshore wind farm. There are so many variables at play at any given time that an accurate and time-sensitive system is necessary.

Ascertra-SeaRoc Limited offers a system in SeaPlanner that can help reduce overall costs during Operations and Maintenance (O&M). By offering a framework from which you can ensure the best possible access to offshore plant, minimising the downtime associated with unscheduled maintenance and increasing efficiency of planned maintenance, the lowest possible cost of energy can be achieved in the long-term.